Water

Case:

IMPROVING THE DEWATERING PROCESS

TURKU WATER | FINLAND

By treating wastewater with ultrasound, dry material content was increased by 2 %, which led to significant savings in process and transfer costs.

ISSUE

Sludge, referring to the material generated in and removed from wastewater treatment plants, contains approximately 95% water. This high water content makes the sludge difficult to handle: Altum provides a way to improve the dewatering process in a way that is both environment and equipment friendly. Dewatering efficiently decreases overall pressure on the process equipment while ensuring better separation and lower costs.

The objective with this customer was to increase dry material content of the sludge as measured after the centrifuge by efficiently separating water from the solids.

SOLUTION

In the dewatering process, ultrasound disrupts the extracellular polymeric substances (EPS) that bind water to sediment, making separation simple. Essentially, ultrasonic treatment can be used to break up bonds in the sludge and thus release the water bound into it.

This facility uses centrifugal dewatering, and Altum’s multichannel solution was installed on a pipeline before the centrifuge to affect the bonds in the sludge and thus enhance the effect of the centrifugal dewatering.

RESULTS

Samples of both the material after the centrifuge and the centrifuge reject water were monitored. The improvement in the dry material content of the waste was over 2%: this reduces the amount of sludge in the plant circulation, as well as makes the other processes of the facility more efficient. Increasing the dry material content leads to many other benefits, such as longer equipment lifespan and lower processing costs, as drier materials occupy less space during storage and transfer.

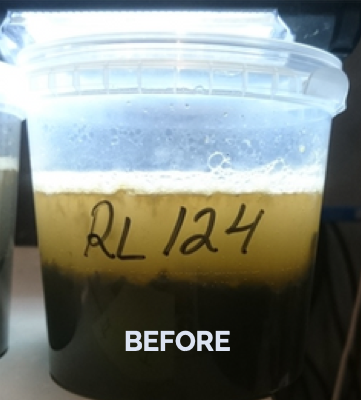

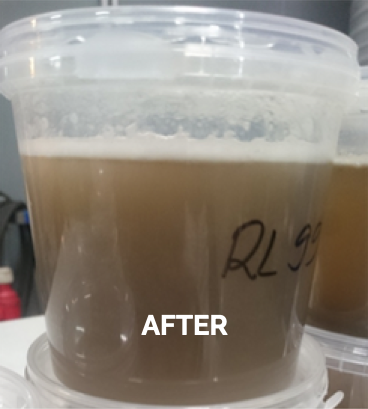

Before and after sonication: no visible dry material in the reject water after sonication.

BENEFITS OF ALTUM'S SOLUTION

-

2% INCREASE IN DRY MATERIAL CONTENT

-

REDUCED PROCESS & TRANSFER COSTS

-

LOWER CO2 EMISSIONS

-

LESS EQUIPMENT WEAR