FOOD & BEVERAGE

Chemical-free cleaning and prevention to minimize process downtime

THE PROBLEM: HIGH COSTS AND DOWNTIME TO MAINTAIN CLEANLINESS

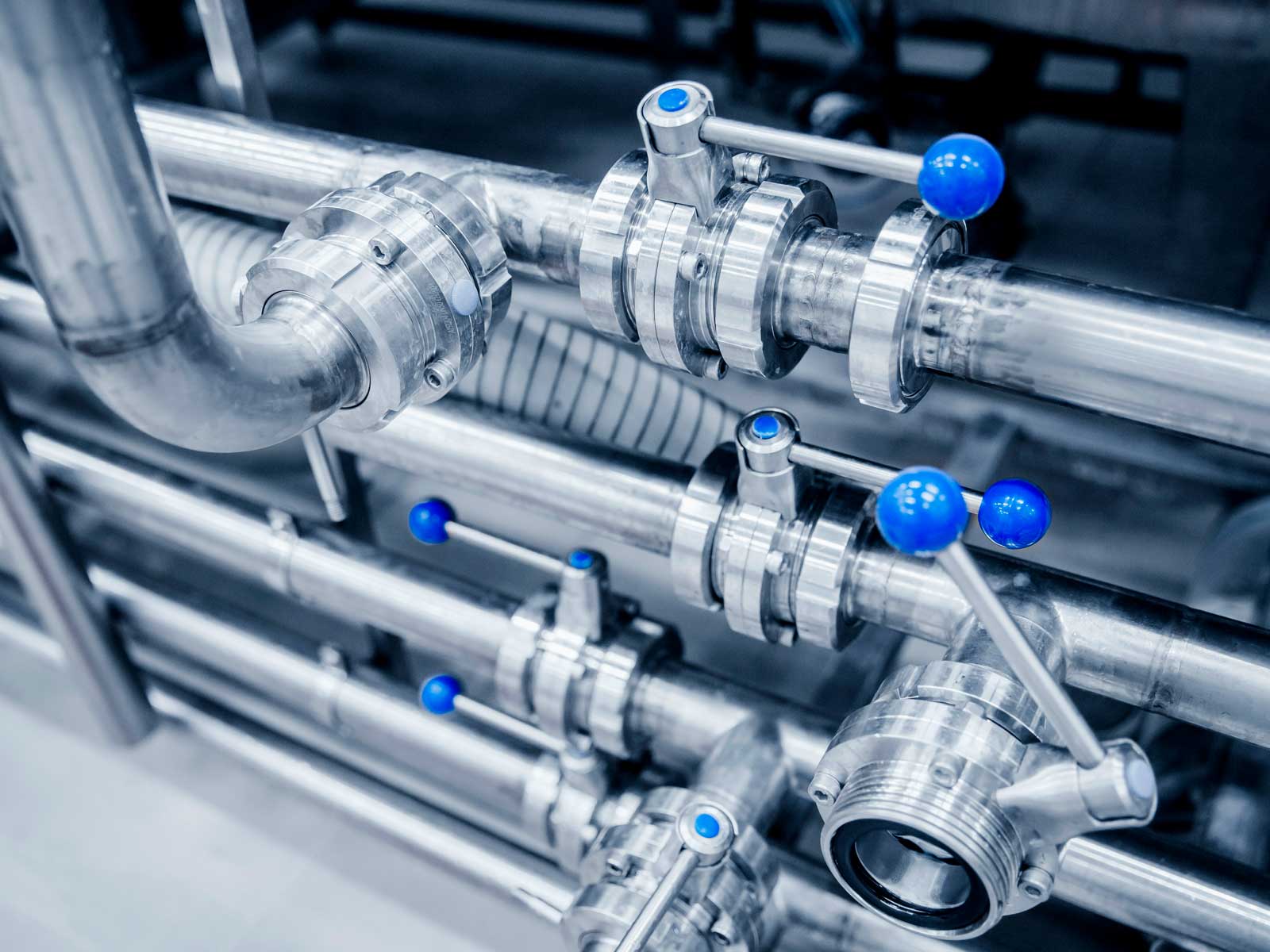

Food production has distinctive characteristics which distinguish it from other process industries, such as short batch-type production processes due to variable market demands and high requirements for quality and cleanliness.

Cleaning is the key to most food industry processes. Achieving maximum hygienic performance is traditionally obtained via a combination of Clean-in-Place (CIP) and manual cleaning. These two methods have a high cost and production capacity is often reduced by lengthy washes.

Luckily, Altum’s high-power ultrasound solution can effectively remove or prevent food soil from happening altogether.

THE BENEFITS OF ALTUM’S ZPD ULTRASOUND TECHNOLOGY IN FOOD & BEVERAGE PRODUCTION:

- Removes food soil like burnt-in sugar or proteins that CIP (Clean-in-Place) methods can’t, and protects your end products from contamination by these residues.

- Improves the mechanical effect of chemical cleaning, reaching places where the design does not allow easy access and washing is therefore poor

- Prevents clogging in sensitive places.

- Emulsifies fatty soils and formulas, allowing you to easily get rid of fat deposits in places where CIP/caustic can’t be used.

- Homogenizes products, thus making them and the equipment less prone to fouling.

- Has a mild disinfectant effect that combines with chemical disinfection to make it more efficient.

RESULTS ACHIEVED IN THE FOOD INDUSTRY