Water is an essential resource in the pulp and paper (P&P) industry, and plays a crucial role in various stages of production from pulping to bleaching and paper formation. This makes the P&P industry one of the largest consumers of water and highlights the importance of efficient wastewater management.

Managing wastewater in the P&P industry presents several challenges, including the treatment of large volumes of effluent while maintaining evaporator functionality, and efficient dewatering while keeping energy consumption and process costs under control. These challenges are added to by strict environmental regulations that drive the need for more sustainable practices.

This article will explore two key aspects of wastewater management in pulp and paper mills: effluent management and dewatering. We’ll address various operational challenges and highlight how ultrasound technology can provide a modern solution.

Key Operational Challenges in Wastewater Management

Effluent Management: Taking Care Of Evaporation Efficiency

Effluent evaporators are used to concentrate and reduce the volume of wastewater generated during the production processes (=effluent) by evaporating the water content. This helps in recovering valuable chemicals or raw materials, such as salts or lignin, and reducing the load on subsequent treatment processes. Effluent from the P&P industry must be treated to remove these contaminants before being discharged into the environment to comply with environmental regulations and minimize ecological impact. The wastewater is heated, causing the water to evaporate and leave behind concentrated effluent. The evaporated water is then condensed and can be reused within the mill or treated further for discharge.

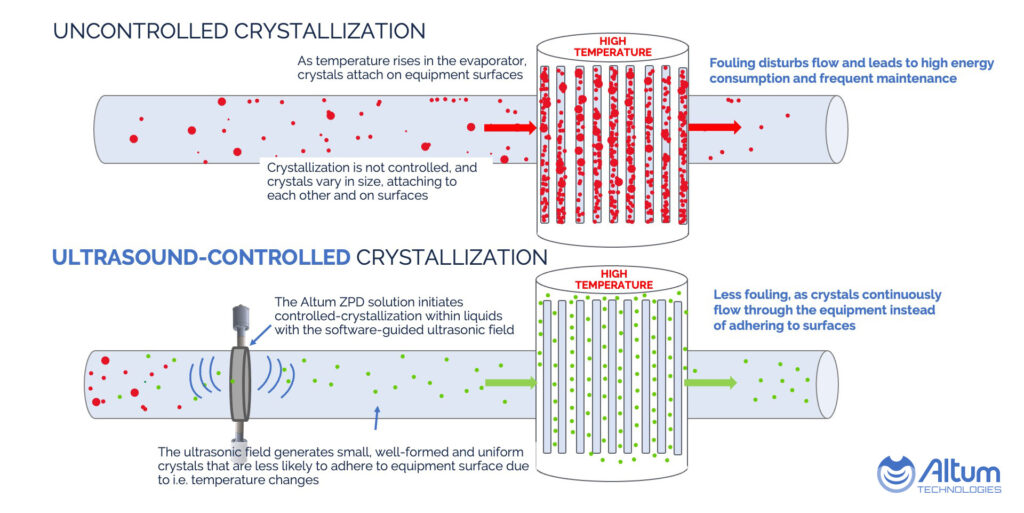

A key challenge in this process is scale formation in the evaporator. In the case of a lamella evaporator, for example, the lamellas can become completely clogged within weeks. This makes it impossible to continue the evaporation process, and requires the process to be stopped for cleaning. These evaporators often require mechanical cleaning, or even the use of special cleaning robots; these methods can be labor-intensive, expensive, and take up a lot of time. Even before the evaporator loses all operation capacity, its energy efficiency is reduced. Fouling decreases the heat transfer efficiency, leading to higher energy consumption to achieve the same level of evaporation.

If the evaporator get clogged or loses efficiency, the efficiency of water recycling decreases with it. This means that valuable water resources might be lost.

Sludge Dewatering: Combatting High Costs

Sludge dewatering, which typically occurs after effluent evaporation, refers to a process that separates solid and liquid elements, making it simpler and more economical to manage each phase individually before ultimately disposing of them in a dry form. The objective is to extract water from the liquid sludge, transforming it into a semi-solid or solid mud block.

A key issue in dewatering is getting it to be as efficient as possible. Efficient dewatering is crucial because wet sludge is difficult and costly to handle and transport. Dewatering itself is energy-intensive, but if done efficiently, the sludge can be burned to generate energy for the mill. Fouling can also pose a significant issue in dewatering equipment, creating blockages and disturbing flow.

Environmental regulations are a significant consideration for both processes. Inefficiency can result in water being released into nature that doesn’t meet quality standards. Regional regulations specify requirements for water pH, chlorinated compounds, heavy metals, and organic pollutants to minimize pollution. Breaking these regulations is both an environmental risk and a big expense. In addition to regulations regarding water quality, the amount of CO2 emitted by mills is also subject to many regional and international regulations.

Cost Impact of Inefficient Wastewater Management

These operational challenges also come with significant cost impacts. For evaporators, main expenses caused by operational challenges are related to fouling. If the evaporator gets blocked, cleaning methods like chemicals and cleaning robots generate their own costs. Especially as these evaporators can often require cleaning many times a year, these costs can become quite substantial.

The main cost impact of handling sludge arises from storing and transporting it when it’s too wet. In addition to this, high energy consumption of the dewatering process itself can be a big cost, especially if fouling disturbs proper flow. If the mill can’t utilize sludge burning, it won’t be able to use the energy produced to cover the high energy use of the operation.

Environmental regulations can also lead to significant expenses if inefficiencies in the wastewater management process result in water being released into nature without meeting required standards. In areas with These penalties for non-compliance can be substantial.

Modern Solution to Improve Efficiency – High-Power Ultrasound

Luckily, there are modern solutions to help mills solve these challenges and improve cost efficiency. We here at Altum Technologies offer a high-power and software-guided ultrasound solution for fouling prevention and efficient dewatering. We have extensive experience in maintaining evaporator efficiency through fouling prevention and improving dewatering efficiency to increase dry material content.

We’ve achieved excellent results in maintaining and improving evaporator efficiency to decrease maintenance and improve uptime. You can read more about our evaporator cases here. Altum’s high-power ultrasound solution prevents fouling in evaporators, often calcium-based, by inducing a crystallization effect. By sonicating the liquid before it goes through the heated elements in an evaporator, ultrasound can induce nucleation and create a controlled crystallization effect so that particles will not adhere to heated surfaces in tubes or lamellas as scale. This means the evaporator stays clean, and operations can function as intended without frequent cleaning breaks.

Ultrasonic sludge dewatering is a wastewater remediation technique that uses high-frequency sound waves to separate sludge from water. Altum’s ultrasound has been proven to both increase the dry material content and enhance the process as a whole by decreasing strain on the equipment used and improving reject water quality. Ultrasound disrupts the extracellular polymeric substances (EPS) that bind water to sediment, making separation simple. Essentially, ultrasonic treatment can be used to break up bonds in the sludge and thus release the water bound into it. Once the sludge is transformed into a more solid form, transporting it and managing it requires less energy.

Benefits of using Altum’s solution

Operational improvements include:

- More stable and efficient effluent evaporation and dewatering processes

- Reduced cleaning shutdowns = more process uptime

- Less equipment wear = longer lifespan

- Higher water recycling rates possible

- More consistent water quality

Economic and sustainability impacts include:

- Reduced maintenance & operational costs due to less cleaning required and lower energy consumption and costs for sludge storage and transportation

- Fewer chemical additives needed

- Less energy required = lower CO2 emissions

- Better resource utilization = water can be recycled more efficiently

Results achieved with Altum’s ultrasound

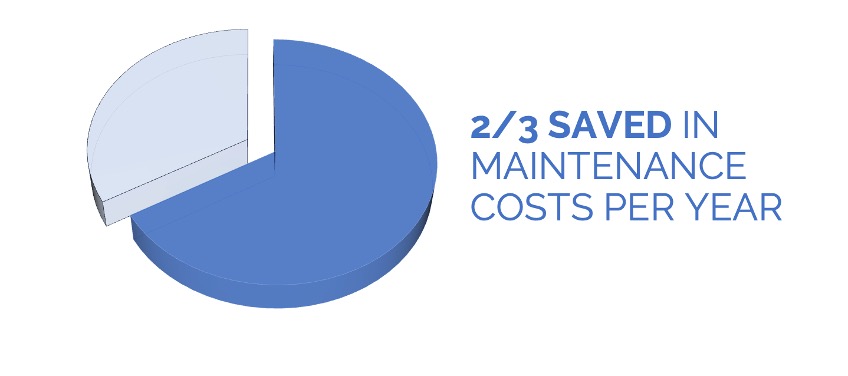

In effluent evaporators, the main benefits are achieved when efficient fouling prevention removes the need for frequent cleaning shutdowns using mechanical methods or chemicals.

With one of our customers, struggling with frequent shutdowns and expensive cleaning with chemicals and cleaning robots caused by fouling, we’ve been able to reduce fouling to the extent that the customer has been able to get rid of mechanical and chemical cleaning altogether. This means savings of approximately 2/3 in maintenance costs on a yearly level.

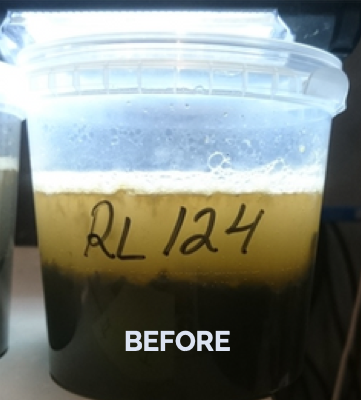

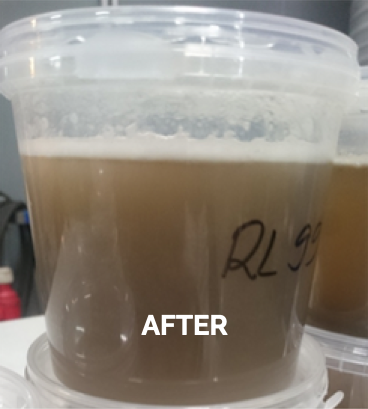

In dewatering processes, we’ve had great successes in increasing the dry material content of the sludge. In one of our cases, the dry material content of the waste improved by over 2%, reducing the amount of sludge in the plant circulation and enhancing the efficiency of other processes. The centrifuge used for dewatering remained significantly more stable and there was a significant decrease in the amount of vibration. In another case, dry material content was increased by up to 5% and the sludge became easier to run: one clear example of this was how the sludge on the dryer belt was significantly less spread out with ultrasonic treatment. Reject water samples were also clearer, containing fewer solid particles. Read more about our dewatering cases here.

Before and after sonication: no visible dry material in the reject water after sonication.

Conclusion – Better Resource Utilization and Lower Environmental Impact

Efficient wastewater management is crucial for the pulp and paper industry to minimize environmental impact and reduce operational costs. Modern solutions, such as Altum’s high-power ultrasound technology, offer promising advancements in preventing fouling and enhancing dewatering efficiency. We can not only help in maintaining process efficiency but also contribute to better resource utilization and lower environmental footprint.

If you’d like to learn more about using Altum’s technology to improve wastewater management, please contact our experts.

Follow us on LinkedIn so you won’t miss our future news and insights.