Clean-in-place (CIP) systems have changed the way facilities clean and sanitize their production lines without the need for disassembly to save valuable time and resources. This article will explore features of these systems and some innovative alternatives transforming the industry.

What Is a CIP System?

A CIP system is an automated cleaning solution that typically circulates detergents, water, and disinfectants through pipes, vessels, and processing equipment without disassembly. Newer versions utilize alternatives to chemicals, such as high-temperature water/steam, ultrasound, electrolyzed water, UV light, and CO₂. These CIP systems are critical in industries where hygiene standards are stringent, and production downtime must be minimized.

CIP equipment typically includes:

- Storage tanks for cleaning solutions and water

- Pumps for circulation

- Heat exchangers to maintain optimal cleaning temperatures

- Spray devices for tank cleaning

- Control systems to manage the cleaning process

- CIP skids that house these components in a modular unit

CIP Tank and Pipe Cleaning Solutions

Across multiple industries, from pharmaceuticals to chemicals and beverage production, CIP tank cleaning systems and pipe cleaning solutions are essential infrastructure. These systems address the unique challenges of cleaning enclosed vessels and complex piping networks where manual cleaning is impractical or impossible.

Traditional CIP skids are designed to deliver precise cleaning parameters: they optimize flow rates, temperatures, chemical concentrations, and contact times to ensure effective cleaning while minimizing resources. For tanks specifically, specialized spray balls or rotary jet heads create high-impact washing patterns that reach every interior surface, while pipe systems rely on carefully calculated turbulent flow to scour internal surfaces clean. Effective cleaning-in-place system design is crucial for ensuring these parameters work harmoniously together.

CIP Systems in the Food Industry

The food and beverage industry especially relies heavily on CIP systems to maintain compliance with safety and quality regulations. These CIP sanitation systems effectively clean tanks, pipes, and processing equipment that come into contact with food products to prevent cross-contamination and ensure product integrity.

CIP tank cleaning systems are particularly valuable for large vessels used in dairy processing, brewing, and other food manufacturing operations. Using specialized spray balls or rotary jet heads, these systems ensure complete coverage of interior surfaces, removing residues that could harbor bacteria through thorough washing cycles.

However, newer CIP systems, such as a clamp-on ultrasound solution, provide efficient cleaning across industries without the extensive piping, pumps, and chemical storage traditionally required.

Is There an Alternative to Traditional CIP Systems?

While conventional CIP systems have served industries well, they come with certain limitations:

- Extensive use of chemicals

- High water consumption

- Need for direct access to equipment

- Installation of often extensive CIP skid systems near equipment

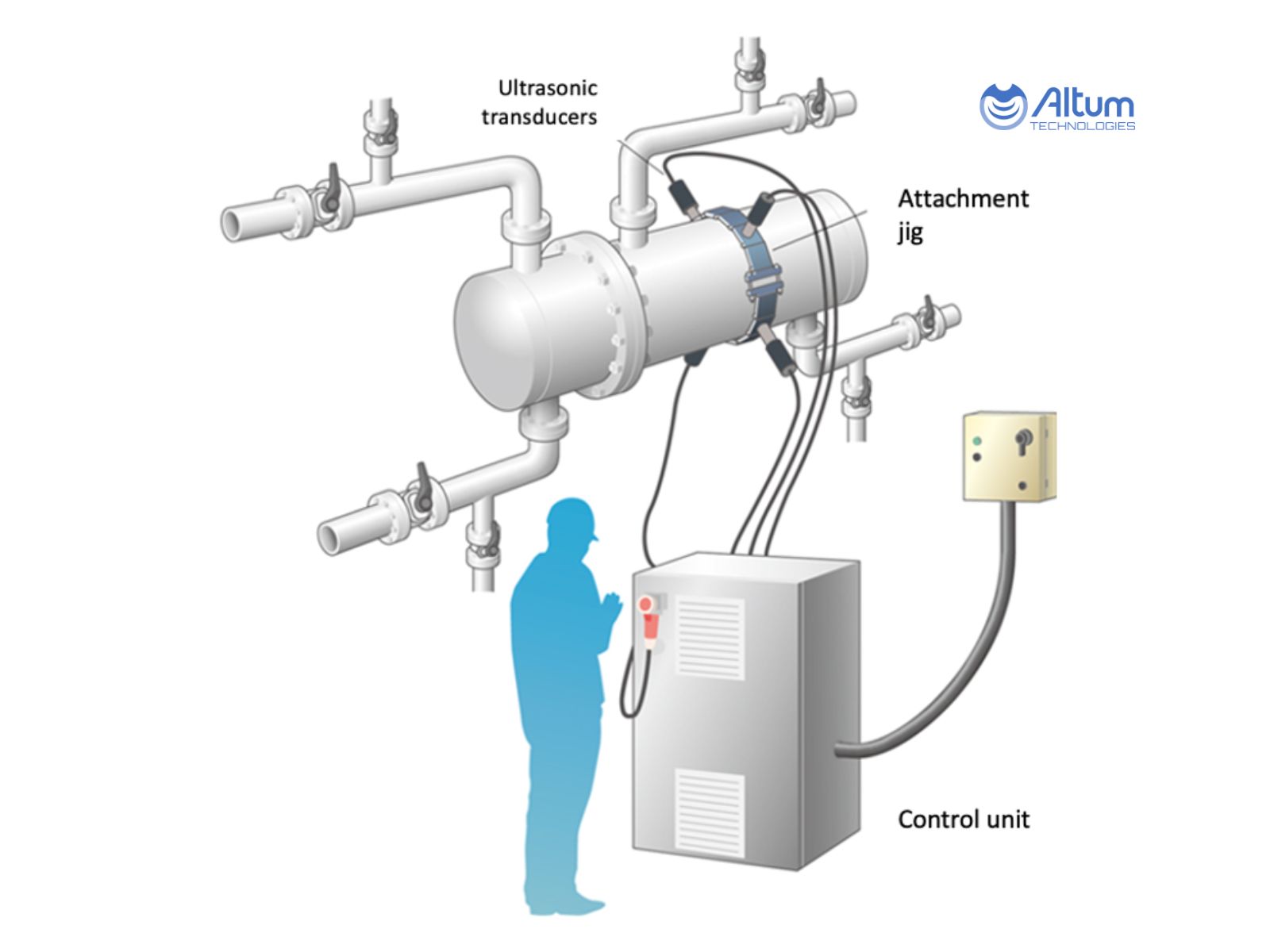

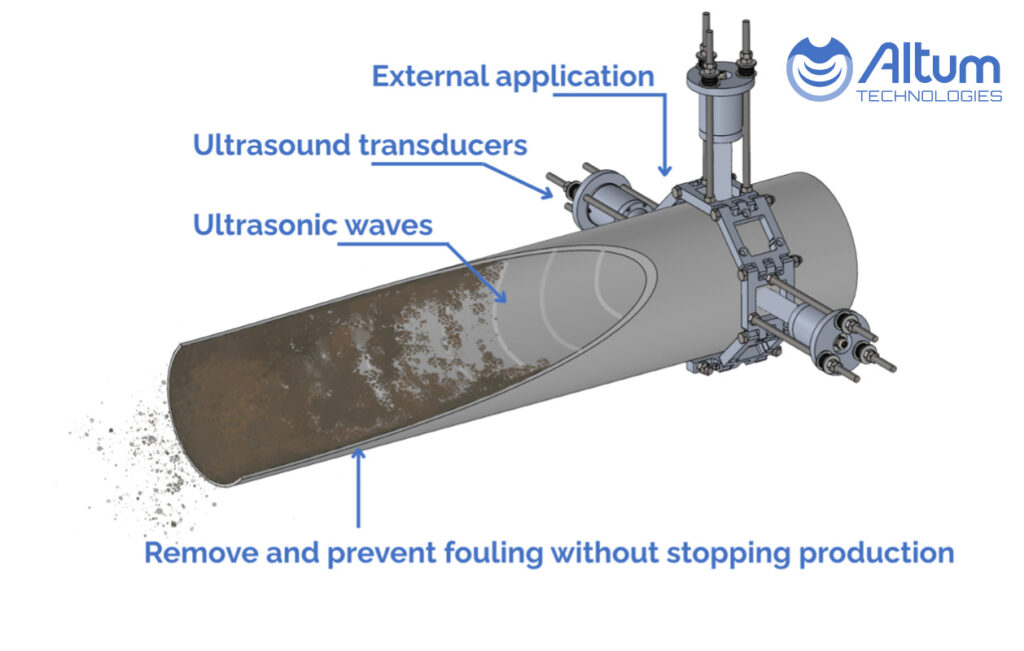

High-power ultrasound technology, such as that developed by Altum Technologies, offers an alternative. This innovative approach applies ultrasound transducers externally to the equipment, which then direct ultrasonic sound waves into the liquid flowing inside to prevent fouling or clean up the equipment. This creates several notable advantages:

- Chemical-free operation, reducing environmental impact and costs

- External application, with an easy-to-install clamp-on device connected to a central unit with cables

- Flexible central unit placement that doesn’t need to be in immediate proximity to the equipment

- Reduced water usage compared to traditional CIP systems

This approach eliminates the need for bulky CIP skids and their associated infrastructure, while allowing cleaning to occur without disrupting production.

Illustration of how Altum’s high-power ultrasound CIP system prevents and removes fouling in an industrial pipe.

Choosing the Right CIP System

When selecting between traditional CIP skid system manufacturers and newer technologies, consider:

- Your specific cleaning requirements

- Environmental impact concerns

- Operational constraints

- Long-term cost projections

CIP skid systems remain a good choice for many operations, particularly those with existing infrastructure designed around conventional clean-in-place equipment. However, for facilities looking to reduce chemical usage or clean equipment without needing a big setup right next to it, ultrasonic solutions provide a valuable alternative.

Conclusion

Whether you opt for a traditional CIP clean-in-place system or explore newer ultrasonic technologies, ensuring proper cleaning of processing equipment remains essential for process efficiency, product quality, and safety. As industries continue to evolve, so too will the methods we use to maintain them. This means moving toward more efficient, sustainable, and effective cleaning solutions.

Are you interested to learn more about using Altum’s ultrasound solution to keep your equipment clean? Contact our experts to find out more.

You can also read more about our technology here: https://altumtechnologies.com/company/technology/

Follow us on LinkedIn so you won’t miss our future news and insights.