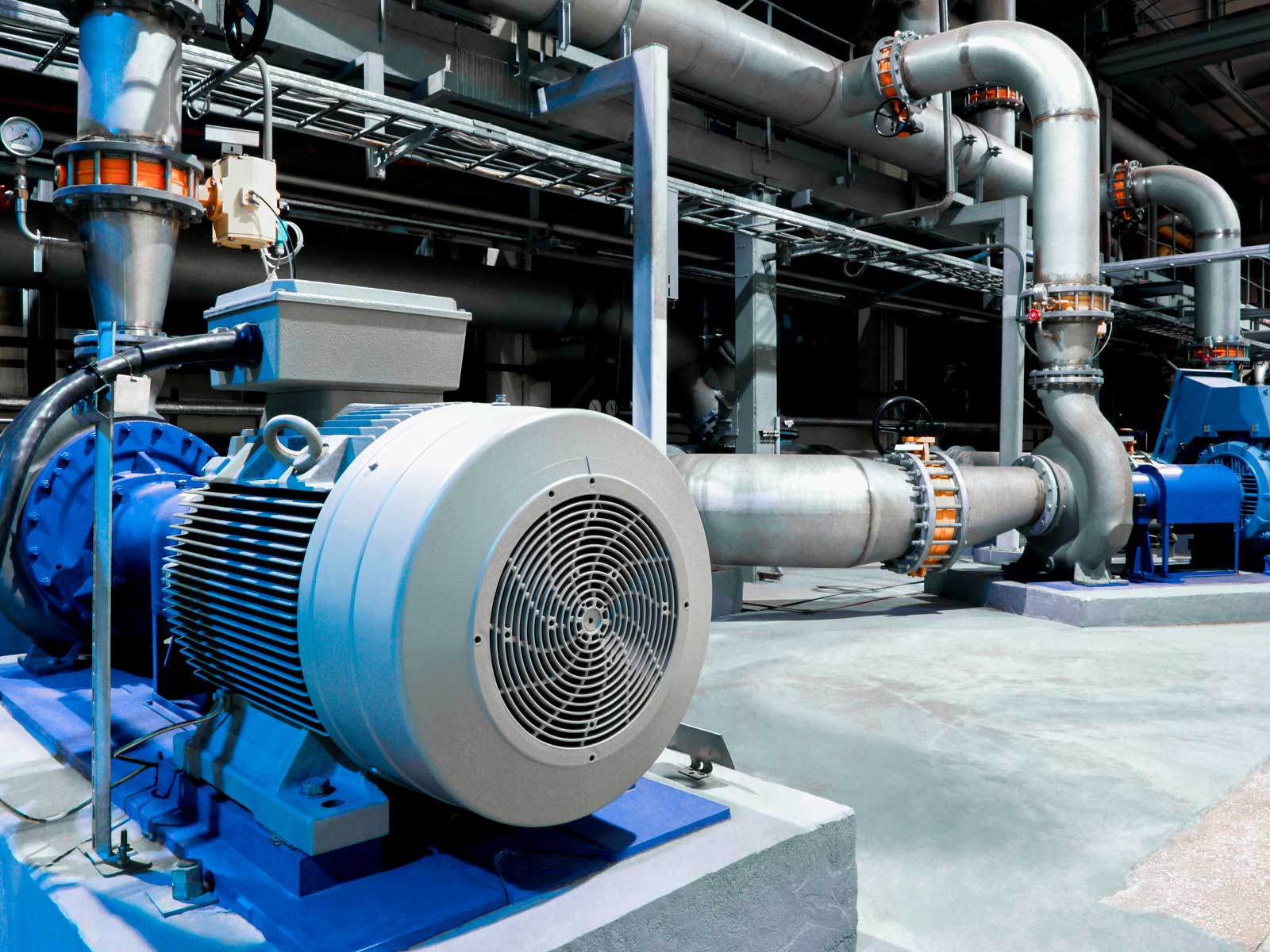

PUMPS & VALVES

Improving efficiency in pumps & valves

Chemical-free fouling prevention and removal to reach Zero Process Downtime

THE USUAL FOULING CHALLENGES

Scaling in pumps and valves can cause excessive wear and reduced pumping efficiency and control, raising costs.

Scaling deposits in pumps are a common source of problems that can lead to both excessive wear as well as higher energy pumping costs. If impellers or housings become coated with scale, this can then also negatively impact on the bearings, shaft and motor.

In valves too, process efficiency and precision can be compromised by scale and fouling that builds and either jams the valve or causing it to control flow rates much less accurately.

THE BENEFITS OF USING ZPD ULTRASONIC TECHNOLOGY ON PUMPS & VALVES INCLUDE:

-

Any type of scaling can be prevented

-

Pump efficiency stays at the designed level

-

Increased equipment lifetime, due to less blockage, wear and tear

-

Improved end-product quality and overall process stability and control

REFERENCES IN PUMP & VALVE APPLICATIONS