APPLICATIONS

Using ultrasound to solve fouling issues in pipes, evaporators, pumps and valves for increased efficiency, less downtime, and improved output.

FOR PIPES

Fouling poses a significant challenge in processes where fluid is transferred in pipes. Buildup of materials transferred often gathers on pipe surfaces. A common way to solve this is to shut down the process and mechanically clean the pipes. Another possibility is to use chemicals to dissolve the build up inside of the pipes. Fortunately, there is now an easier, more effective option: Altum’s ZPD (Zero Process Downtime) Ultrasound!

With Altum’s ultrasound, companies are able to keep pipes clean, improve flow, and lower energy consumption.

FOR EVAPORATORS

The accumulation of an undesirable layer of deposits or fouling on the heat-transfer surfaces causes significant and expensive issues for both operation and maintenance of the evaporators. The fouling can decrease the evaporator’s energy efficiency and increase CO2 emissions of the evaporation process.

With’s Altum’s ultrasound, companies have been able to:

- Increase evaporator uptime by up to 300%

- Lower CO2 emissions by hundreds of tons

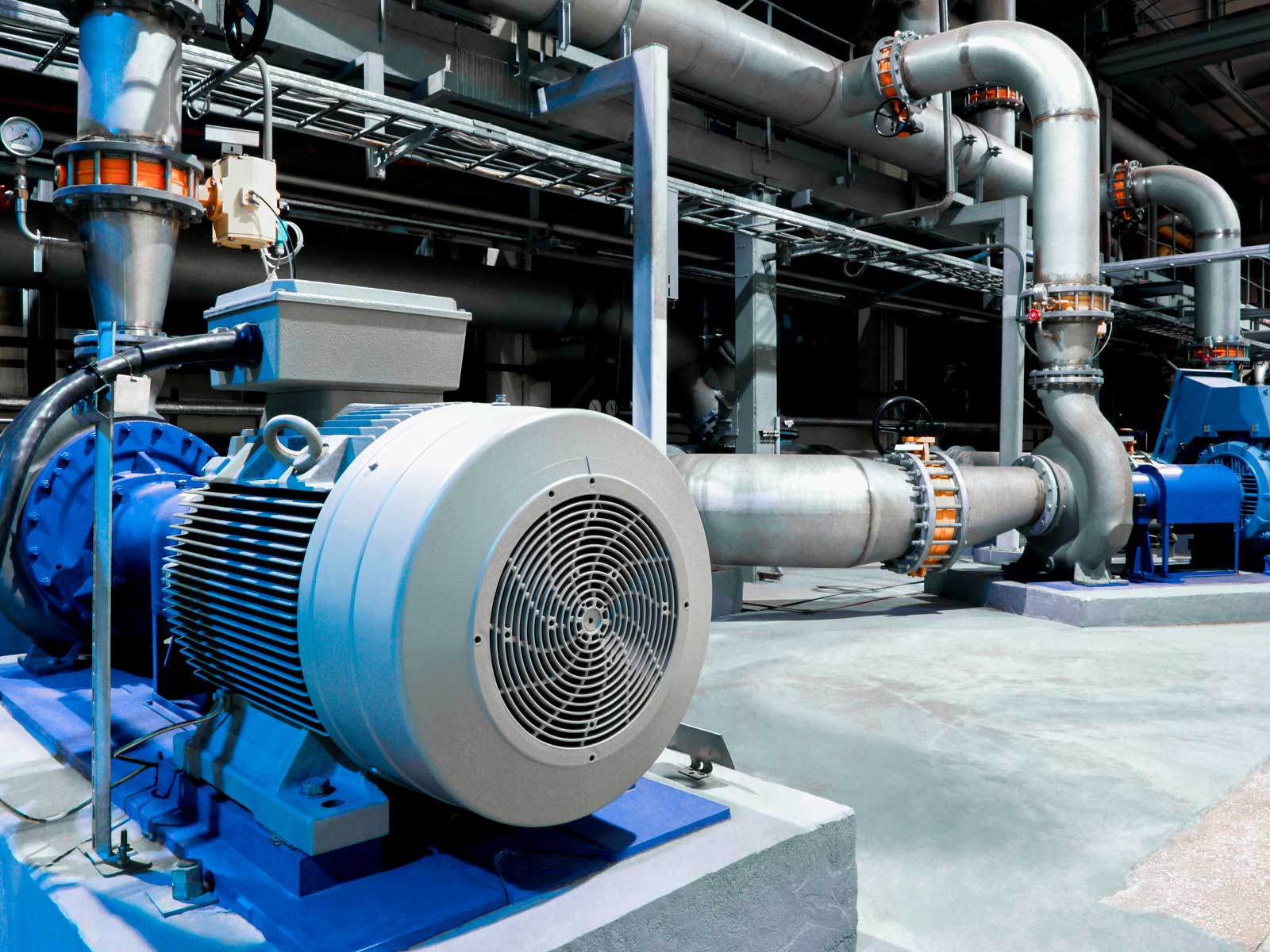

FOR PUMPS & VALVES

Scaling deposits in pumps are a common source of problems that can lead to both excessive wear as well as higher energy pumping costs. If impellers or housings become coated with scale, this can then also negatively impact on the bearings, shaft and motor.

With Altum’s solution, companies are able to keep valves and pumps fully operational and lower equipment strain.