Scale buildup is one of the most persistent and costly problems that industrial facilities face. Different mineral deposits like calcium carbonate clog equipment like pipes, heat exchangers and black liquor evaporators. Using efficient descaling methods is essential for maintaining operational efficiency and extending equipment lifespan.

This article will explain descaling in general, introduce the process of scale formation and showcase different descaling methods.

What Is Descaling?

Descaling is the process of removing mineral and chemical deposits that accumulate on surfaces exposed to water or other process fluids. Descaling is a critical maintenance procedure that restores efficiency, prevents equipment failure, and reduces energy consumption.

Scale forms when dissolved minerals, salts, or chemical compounds precipitate out of solution and stick to equipment surfaces. This buildup acts as an insulator on heat transfer surfaces, which forces systems to work harder and reduces heat transfer efficiency by up to 30-50%. Scale can cause severe damage to equipment if not managed properly, leading to equipment failure. This, in turn, requires expensive repairs or replacements.

Understanding Industrial Scale Formation

Scale formation occurs in many different industrial processes through various chemical and physical mechanisms:

Water-based systems: Calcium carbonate, calcium sulfate, silica, and iron oxide deposits form in pipes, boilers, heat exchangers, cooling towers, and HVAC systems when hard water is heated or experiences pressure changes.

Pulp and paper manufacturing: Black liquor, which is the by-product of the kraft pulp process, contains high concentrations of dissolved calcium and sodium compounds. As black liquor is concentrated in evaporators and burned in recovery boilers, calcium carbonate and calcium sulfate scales accumulate on tubes and surfaces. This severely impacts heat transfer and system reliability.

Petroleum refining: Crude oil processing generates scale from sulfur compounds, salt deposits, and heavy metal precipitation in distillation units,

Chemical processing: Reaction byproducts, crystallization from saturated solutions, and polymer deposits create scale in reactors, distillation equipment, and heat exchangers in various solvents and process fluids.

Food and beverage: Protein deposits in dairy processing, sugar crystallization in refineries, and mineral accumulation in brewing operations all create scaling challenges that require regular attention.

The financial impact is substantial across all these applications. Energy costs increase as fouled equipment works harder. Maintenance expenses rise, and production downtime means less production and less revenue. For many facilities, scale-related issues represent hundreds of thousands of dollars in annual losses.

Chemical Descaling: The Traditional Approach

Chemical descaling remains the most widely used method in industrial facilities. A descaling agent dissolves mineral deposits through acidic or chelating reactions, which then breaks crystalline structures so they can be flushed away.

Common descaling chemicals include:

Hydrochloric acid: This acid is effective but extremely corrosive and requires careful handling and safety protocols. It can damage equipment if not properly neutralized and poses significant environmental and worker safety risks.

Citric acid: A biodegradable organic acid offering a safer alternative for less severe scaling. While gentler, it requires longer contact times and may not be effective against heavy deposits.

Sulfamic acid: Commonly used as a heat exchanger descaler. It is quite effective and less corrosive compared to hydrochloric acid.

Rydlyme descaler: This proprietary biodegradable solution works through chelation rather than aggressive acid dissolution, making it safer for equipment and operators while maintaining effectiveness.

The chemical descaling process typically involves circulating the descaling agent through the affected system for several hours, monitoring pH levels, then neutralizing and flushing. While effective, this method presents significant challenges:

- Safety concerns: Handling corrosive chemicals requires protective equipment, ventilation, and trained personnel

- Extended downtime: Chemical descaling often requires 24-48 hours of shutdown for preparation, circulation, neutralization, and flushing

- Environmental impact: Disposal of spent chemicals requires proper treatment and can cause significant costs

- Equipment risk: Acids can damage gaskets, seals, and metal surfaces if exposure isn’t carefully controlled

- Incomplete cleaning: Chemical solutions may not reach all areas of complex geometries, which leaves scale on surfaces

- Process-specific limitations: Some scale types don’t respond to chemical treatment, particularly in non-aqueous systems where acid reactions behave differently

Mechanical Descaling Methods

Mechanical removal is an alternative for when surfaces are accessible. Various descaling tools and descaling machines physically remove scale through abrasion, cutting, or impact.

Different options for mechanical industrial descaler equipment include:

- Rotary cleaning systems: Wire brushes or abrasive pads on flexible shafts that go through piping systems

- Hydroblasting: High-pressure water jets that remove deposits

- Pneumatic descaling hammers: Impact tools for heavy and often thick scale buildup

- Tube cleaning systems: Specialized descaler machine equipment designed for heat exchanger tube bundles

Mechanical descaling can be highly effective for external surfaces and accessible areas but it has its limitations. Internal surfaces of complex systems, where scale causes the most problems, often can’t be reached. Mechanical methods also require equipment disassembly, which leads to extended downtime and labor costs.

Another thing to consider is the risk of damaging underlying surfaces. Aggressive cleaning can damage metal. This creates nucleation sites, which attract new scale deposits. Heat exchanger tubes are particularly vulnerable and can be damaged by excessive force.

Scale Prevention Strategies

While descaling addresses existing deposits, scale prevention focuses on stopping formation before it occurs.

Here are some examples of prevention methods:

Water treatment: Softening removes calcium and magnesium before entering systems. Effective but requires ongoing maintenance and consumables.

Chemical inhibitors: Additives that interfere with scale crystal formation, requiring continuous dosing and monitoring.

Calcium descaler devices: Point-of-use systems address scales at specific locations, ranging from simple filters to sophisticated treatment systems.

The challenge with prevention-only approaches is that they don’t address existing scale deposits. Most industrial systems already have some degree of scaling impacting efficiency. Combining prevention with effective descaling provides the most comprehensive solution.

Ultrasonic Descaling: The Advanced Industrial Solution

Ultrasonic descaling technology represents a fundamental advancement in scale management. Unlike chemical or mechanical methods, ultrasound uses high-frequency sound waves to remove and prevent scale deposits without chemicals, disassembly, or system downtime.

How Does Ultrasonic Descaling Work?

The term ultrasound refers to sound waves with frequencies above 20 kilohertz (kHz). Ultrasonic transducers used in industrial applications, such as Altum Technologies’ high-power ultrasound solution, generate sound wavestypically from 20 kHz to several MHz, which are transmitted through equipment walls into the fluid inside. Lower frequencies are generally better for penetrating thicker materials. Altum’s high-power ultrasound solution consists of a clamp-on belt with ultrasound transducers, which are applied onto the equipment. Ultrasound waves created by Altum’s solution can create microscopic bubbles through cavitation, microscopic vibrations or sonocrystallization, which all prevent or remove fouling.

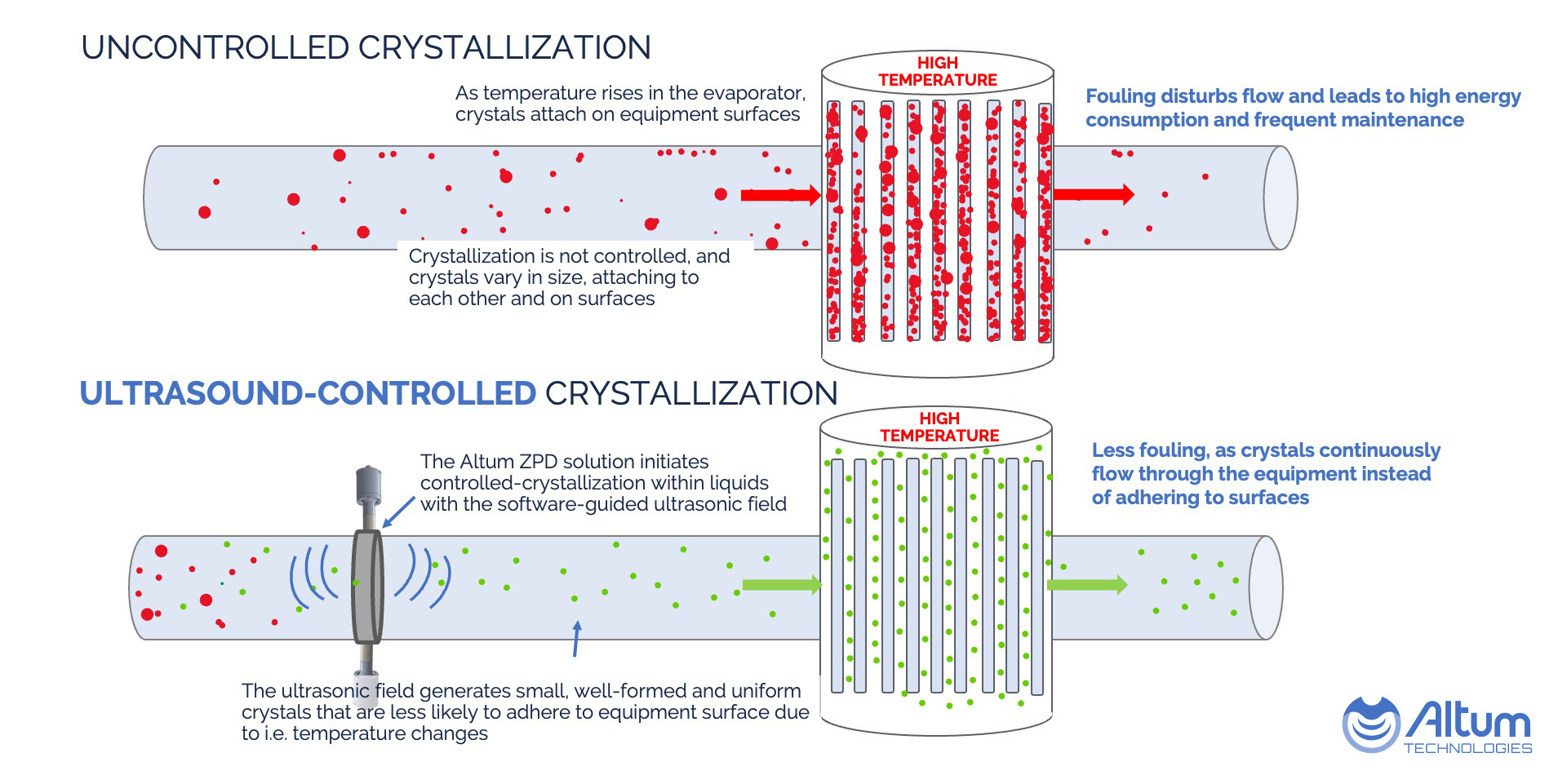

When it comes to mineral scaling, sonocrystallization is a very efficient method to prevent fouling in the process. This is especially useful when preventing fouling caused by non-organic salts, often found in black liquor evaporators, heaters, or concentrators. By sonicating the liquid, like black liquor, before it goes through the heated elements in the equipment, ultrasound can induce nucleation and create a controlled crystallization effect so that the salt crystalswill not adhere to heated surfaces as scale. See the picture below for a visual explanation.

Advantages Over Traditional Methods

Chemical-free operation: Altum’s ultrasonic descaling eliminates descaling agents and descaling chemicals entirely. No safety concerns with corrosive substances, no environmental impact from disposal, and no acid damage risk. Facilities save substantially on chemical purchase and disposal costs.

Zero downtime: Altum’s ultrasonic transducers install externally on operating equipment without welding or dismantling, which means there is no need to stop production to start prevention. The descaling system operatescontinuously during normal production.

Complete coverage: Chemical and mechanical methods struggle with complex geometries and hard-to-reach areas. Especially when utilizing sonocrystallization, Altum’s ultrasound affects the liquid itself, and can create a very long-lasting effect.

Equipment protection: Mechanical tools can damage surfaces, and acids corrode metal and weaken components. Ultrasonic descaling operates at the microscopic level, gently loosening scale or preventing it without equipment risk.

Continuous prevention: Traditional descaling is reactive, which means you clean when problems become severe. Our ultrasound technology provides continuous prevention, maintaining optimal efficiency year-round rather than cycling between clean and scaled conditions.

Energy savings: By maintaining clean heat transfer surfaces continuously, Altum’s ultrasonic descaling delivers continuous efficiency improvements. Facilities typically see 10-30% reductions in energy consumption as heat transfer returns to optimal levels.

Versatility across fluids: Our ultrasound technology works effectively in liquid-based systems, black liquor applications, petroleum processes, and chemical operations. The cavitation and vibration mechanisms function regardless of the process fluid, making it adaptable across diverse industrial applications.

Industrial Applications of Ultrasonic Descaling

Ultrasound technology can be utilized in a variety of different industrial processes to prevent and remove scaling.

Pulp and paper: Black liquor evaporators maintain efficiency without chemical or weak black liquor cleaning cycles that impact production schedules.

Heat exchangers: Shell-and-tube, plate, and spiral heat exchangers across all industries maintain heat transfer efficiency without disassembly.

Petroleum refining: Crude oil processing equipment, such as pipes and valves, operate continuously with reduced fouling.

Chemical processing: Pipes, reactors, valves, pumps, distillation equipment, and heat exchangers handling various process fluids benefit from continuous scale management.

Food and beverage: Processing equipment, especially pipes, maintain sanitary conditions and efficiency without harsh chemical exposure.

Power generation: Boilers, pipes, condensers, and cooling systems maintain peak efficiency and reliability.

Choosing the Right Descaling Approach

Selecting the appropriate method depends on several factors:

Severity of existing scale: Heavily scaled systems may benefit from initial aggressive cleaning followed by ultrasonic prevention. Moderately scaled systems can transition directly to ultrasonic treatment, which progressively removes deposits over time and prevents further scaling.

Operational requirements: Facilities that cannot afford downtime require solutions working during normal operations. Operations with scheduled maintenance windows may have more flexibility.

Safety and environmental priorities: Organizations focused on reducing chemical use find ultrasonic solutions align with sustainability goals.

Long-term cost considerations: While chemical descaling may appear less expensive initially, recurring costs for chemicals, labor, downtime, and accelerated equipment replacement make it more expensive over time. It is also worth considering the cost savings that come from keeping the equipment operating at optimal efficiency all the time, such as the cost savings caused by improved energy efficiency and optimal flow rates. Altum’s ultrasonic systemstypically achieve payback within a few months.

Conclusion

Descaling is an important player in achieving industrial efficiency, equipment longevity, and lower operational costs. Whether addressing scale in water systems, black liquor evaporators, petroleum processing, or chemical manufacturing, the right descaling approach significantly impacts your bottom line.

Traditional methods using descaling agents and descaling tools have served industries for decades, but come with substantial limitations in downtime, safety, environmental impact, and both equipment and process-related risk. Industrial chemical descalers remain widely used, but their limitations are also being increasingly recognized across industries.

Altum’s ultrasonic descaling technology was developed to overcome the challenges related to conventional approaches. By eliminating chemicals, operating during production, removing scale and preventing future scale formation, our ultrasonic systems deliver results that chemical and mechanical methods can’t match.

For facilities serious about optimizing efficiency, reducing costs, and implementing sustainable maintenance practices, ultrasonic descaling is an important improvement in their scale management strategy.

Let’s look at your process and see how chemical-free ultrasonic descaling can reduce downtime and improve efficiency.

Don’t forget to follow us on LinkedIn to catch our future insights and news.