Black liquor is a fundamental residual stream of modern pulp and paper manufacturing, and a comprehensive understanding of its properties, applications, and processing challenges is a key aspect of industry know-how. This byproduct of the kraft pulping process plays a crucial role in mill economics, energy generation, and environmental sustainability.

What is Black Liquor?

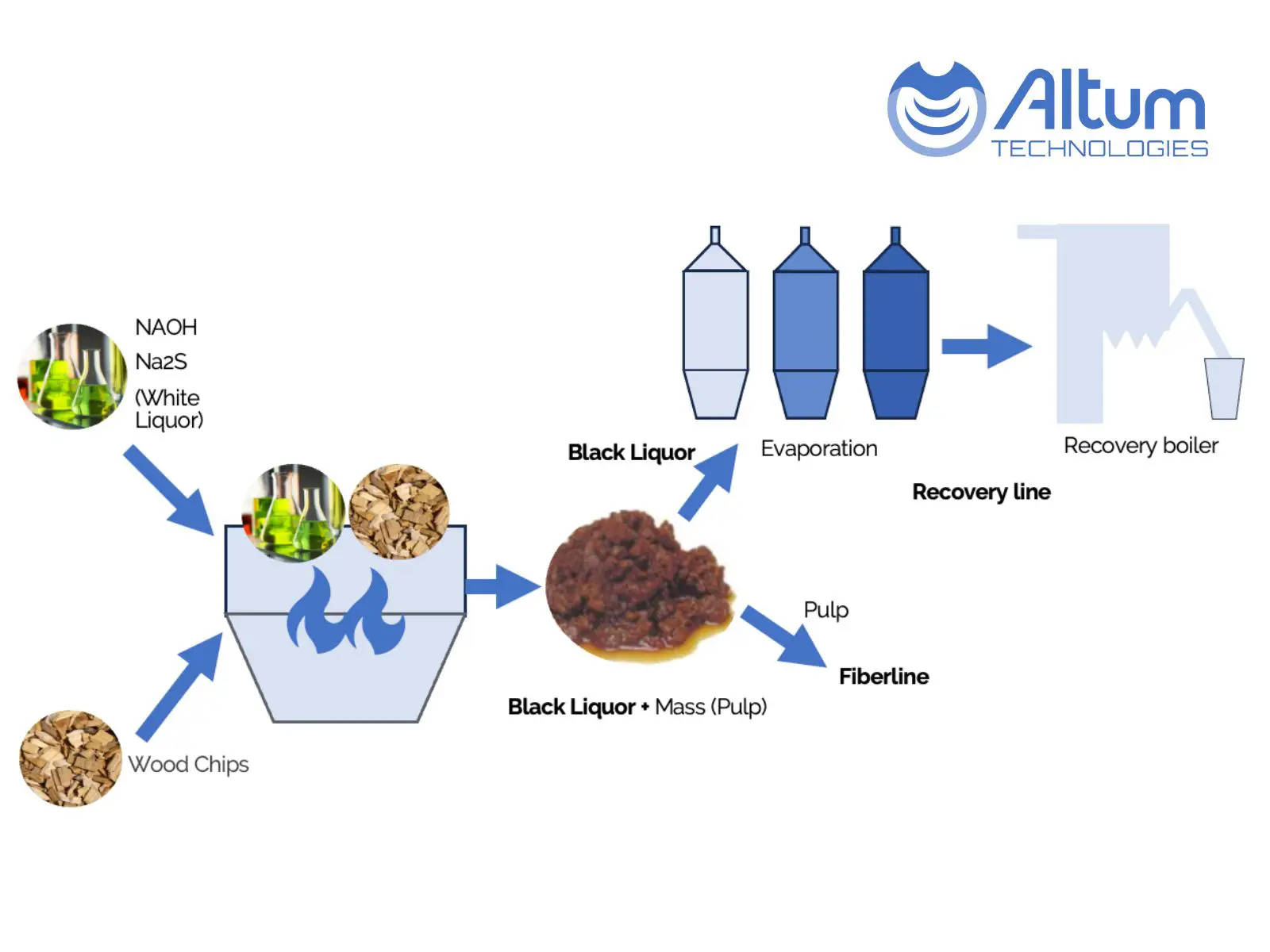

Black liquor is a dark, viscous liquid waste stream generated during the kraft pulping process in pulp and paper mills. When wood chips are digested with sodium hydroxide and sodium sulfide at high temperatures, the lignin and other organic compounds are dissolved, creating this characteristic dark liquid. The name “black liquor” comes from its distinctive dark brown to black color, which is caused by the dissolved lignin and other organic materials.

In the pulp and paper industry, black liquor serves multiple purposes beyond waste management. It contains approximately 15-20% dissolved solids, including valuable chemicals that can be recovered and reused in the pulping process. This makes black liquor recovery an essential component of sustainable mill operations.

The composition and characteristics of black liquor vary significantly depending on several operational factors.

Factors Affecting Black Liquor Composition:

- Cooking conditions in the digester (temperature, time, and pressure)

- Composition of white liquor used in the pulping process

- Quality and species of wood used as raw material

Factors Affecting Dry Solids Content:

- Wood fiber hardness, as harder woods typically yield different lignin content

- Amount of alkali added during cooking (higher alkali dosage increases the inorganic content)

- Evaporation plant performance and process stability: well-functioning and stable operations lead to higher dry solids, increasing black liquor’s heating value and improving combustion efficiency and energy recovery in the recovery boiler.

What is Black Liquor Used For?

Black liquor has several important applications in modern pulp mills:

Energy Production: Black liquor is burned in recovery boilers to generate steam and electricity for mill operations. This makes it a crucial renewable energy source that typically provides 60%-80 of a mill’s energy needs: in some mills the steam generated from burning black liquor provides all the steam needed in the process.

Chemical Recovery: The inorganic chemicals dissolved in black liquor are recovered and converted back into white liquor for reuse in the pulping process, creating a closed-loop chemical cycle.

Research and Development: Emerging applications include the production of bioproducts such as lignin-based chemicals and biofuels, as mills explore opportunities to become integrated biorefineries.

Types of Black Liquor and Related Liquors

Among the various liquors in the kraft process, black liquor stands out due to its volume, energy content, and role in the recovery cycle. However, the process produces several types of liquors that are all interconnected as part of a closed-loop recovery cycle.

Different liquors in the kraft process include:

- Black liquor: The spent cooking liquor produced in kraft (sulfate) pulping processes

- Kraft liquor: Another term for black liquor in kraft mills

- Green liquor: Formed when smelt (containing sodium carbonate and sodium sulfate) from black liquor recovery boilers is dissolved in water.

- White liquor: Formed when lime is added to the green liquor, converting sodium carbonate into sodium hydroxide. The active cooking chemicals (primarily sodium hydroxide and sodium sulfide) used in kraft pulping.

These liquor streams are interconnected in the kraft recovery process, where black liquor is systematically converted back into white liquor through evaporation, combustion, chemical recovery, and causticizing steps. This closed-loop system ensures both chemical recovery and energy generation, making black liquor the most prevalent waste stream in modern pulp mills due to the dominance of kraft pulping technology.

Is Black Liquor Dangerous?

Black liquor presents several operational and safety challenges in kraft pulp mills, particularly related to its physical and chemical properties. Its high temperature and caustic nature require robust material selection, precise process control, and preventive maintenance to ensure safe and efficient operation.

From an equipment standpoint, black liquor can cause corrosion, erosion, and fouling, especially in evaporation plants, piping, and recovery boilers. High dry solids are desirable for combustion efficiency, but they also increase viscosity, placing greater demands on pumps and heat exchangers.

To ensure safe handling, mills must invest in proper system design, reliable instrumentation, and preventive safety measures, including process interlocks and emergency shutdown systems. While the liquor itself is hazardous, well-engineered systems and stable operations mitigate risks to both personnel and equipment.

Black Liquor Recovery Process

The black liquor recovery process is a sophisticated system that transforms waste into valuable resources. After pulping, the black liquor undergoes multiple stages of processing to recover both energy and chemicals

The recovery process begins with evaporation, where black liquor is concentrated from approximately 15% solids to 80-85% solids. This concentrated black liquor is then fired in recovery boilers, where the organic compounds burn to generate steam for mill operations while the inorganic chemicals form a molten smelt.

The smelt is dissolved in water to create green liquor, which is then causticized with lime to regenerate white liquor for reuse in the pulping process. This closed-loop system makes kraft pulping both economically viable and environmentally sustainable.

Black Liquor Evaporation

Black liquor evaporation is critical for preparing it for efficient combustion in recovery boilers. The evaporation process must remove water while concentrating the valuable solids, and this operation presents numerous technical challenges. Typically, mills use multi-effect evaporators, which usually consist of 5-7 process stages. The integration of heaters and concentrators in the evaporation process can significantly improve steam economy and reduce operational issues, and these are often included in modern evaporation processes

As black liquor becomes more concentrated, its viscosity increases dramatically, making it thicker and harder to pump through the system. This higher viscosity also makes it more difficult for heat to transfer effectively, so higher temperatures are needed to keep the liquor flowing properly. The high organic content also makes the liquor prone to thermal degradation at elevated temperatures, which can impact both chemical recovery efficiency and equipment performance.

Additionally, the evaporation plant separates and recovers chemicals from side streams generated during cooking, such as methanol, turpentine, and soap.

Black Liquor Recovery Boiler Operations

Black liquor recovery boilers are massive industrial units that serve as the heart of chemical recovery in kraft mills. These specialized boilers must handle the unique challenges of burning a liquid fuel with high inorganic content while maintaining efficient heat transfer and chemical recovery.

Recovery boilers operate under extreme conditions, with furnace temperatures exceeding 1000°C and complex heat transfer surfaces that are prone to fouling and corrosion. The design must accommodate the dual function of energy generation and chemical recovery while ensuring safe, reliable operation.

Modern recovery boilers incorporate advanced control systems and monitoring technologies to optimize combustion efficiency and minimize environmental emissions. However, operational challenges remain significant, particularly regarding fouling prevention and heat transfer optimization.

Black Liquor Processing and Fouling Issues

Fouling is one of the most significant operational challenges in black liquor processing systems. The complex mixture of organic and inorganic compounds in kraft liquor in addition to high temperatures creates ideal conditions for deposit formation on heat transfer surfaces throughout the recovery system.

Black liquor fouling occurs through multiple mechanisms, including crystallization and chemical precipitation. These deposits reduce heat transfer efficiency, cause pressure drops, and often lead to frequent, even unplanned shutdowns and outages for cleaning. A key challenge is fouling in evaporators, which directly impacts water evaporation efficiency and limits maximum steam generation capacity. When fouling accumulates on heat transfer surfaces, the same amount of steam can no longer evaporate water from the black liquor as efficiently. This leads to increased steam consumption throughout the process and ultimately reducing overall energy efficiency. The economic impact of fouling is significant, consisting of lost production and increased energy consumption due to reduced heat transfer performance.

Understanding fouling mechanisms and implementing effective prevention strategies is essential for maintaining optimal black liquor processing performance. Discover how fouling impacts the entire recovery line and learn about modern prevention approaches.

Maximizing Black Liquor Recovery Efficiency

Achieving optimal black liquor recovery efficiency requires a comprehensive approach that addresses all aspects of the recovery process. From evaporation through combustion and chemical recovery, each step must be optimized to maximize both energy generation and chemical recovery.

Key factors influencing recovery efficiency include black liquor composition, evaporation system performance, recovery boiler operation, and chemical recovery effectiveness. Modern mills employ sophisticated monitoring and control systems to optimize these parameters continuously.

Innovative technologies such as ultrasound-based CIP (Clean-in-Place) and fouling prevention can significantly impact recovery efficiency by maintaining optimal heat transfer and reducing maintenance requirements. See how ultrasound technology increased evaporator uptime by 300% by efficiently preventing fouling.

Sustainability and Modern Black Liquor Processing

The role of black liquor in sustainable pulp and paper manufacturing continues to evolve as mills seek to optimize their environmental performance while maintaining economic competitiveness. Modern black liquor processing technologies focus on maximizing energy recovery, minimizing emissions, and improving overall system efficiency.

In addition to improving process efficiency, advanced fouling prevention technologies also play a crucial role in sustainability efforts by minimizing downtime and optimizing energy utilization by lowering steam usage. Learn how modern fouling prevention supports sustainability goals.

The integration of digital monitoring and control systems also enables more precise optimization of black liquor processing. This leads to improved resource utilization and reduced environmental impact.

Future Trends in Black Liquor Technology

The future of black liquor processing will likely focus on further improvements in energy efficiency, environmental performance, and operational reliability. Emerging technologies include advanced materials for heat transfer surfaces, improved combustion control systems, and integrated biorefineries that extract additional value from black liquor components. It is becoming more important than ever to make sure no valuable resources go to waste.

Digitalization and artificial intelligence are also expected to play increasing roles in optimizing black liquor processing through predictive maintenance, advanced process control, and real-time optimization algorithms.

Conclusion

Black liquor represents both a significant challenge and valuable opportunity for pulp and paper mills. Understanding its properties, processing requirements, and process optimization strategies is essential for achieving efficient, sustainable mill operations.

Success in black liquor processing requires a comprehensive approach that addresses evaporation, combustion, chemical recovery, and fouling prevention. By implementing modern technologies and best practices, mills can maximize the value derived from this important waste stream while minimizing environmental impact.

For mills seeking to optimize their black liquor processing operations, partnering with technology providers who understand the complex challenges of kraft recovery systems is essential for achieving long-term success. Altum Technologies specializes in advanced solutions for fouling prevention, which have been proven to be highly effective in the black liquor recovery process. Contact us to learn how our innovative technologies can improve your mill’s recovery efficiency and operational performance.

Follow us on LinkedIn so you won’t miss our future news and insights.