Pipe systems across the world face a common enemy: fouling. This fouling, buildup of unwanted materials, in pipes can take various forms, including scaling and tuberculation, all of which significantly impair system performance and longevity. These fouling deposits create substantial challenges for facility operators worldwide.

Understanding Pipe Fouling Types

Scaling in pipes occurs when dissolved minerals in water, primarily calcium and magnesium, crystallize and form hard deposits on interior pipe surfaces. This pipe scale gradually restricts flow, reduces efficiency, and increases operational costs. Industrial facilities often face similar scaling in tubing systems throughout their operations. In severe cases, complete pipe scale removal becomes necessary to restore functionality.

Tuberculation in pipes represents another challenging form of fouling, particularly in metal pipes. These mound-like deposits form when corrosion creates rough surfaces where additional material adheres. A tuberculated pipe not only suffers from reduced diameter but also experiences increased friction, elevated energy consumption, and potential contamination issues.

Industrial settings face additional fouling challenges from process materials, while sewer pipelines commonly battle organic build-up and foreign material intrusion. Regardless of the specific environment, effective pipe descaling strategies are essential for system maintenance.

Signs Your Pipes Need Descaling

Watch for these indicators of pipe fouling:

- Decreased water pressure or flow rate

- Inconsistent temperature control

- Increased energy consumption

- Unusual noises from pipe systems

- Discolored water

- Frequent clogs or backups

Effective Pipe Descaling Methods

Modern pipe descaling solutions vary based on fouling type, pipe material, and system application:

For residential and light commercial applications, chemical pipe descalers dissolve mineral deposits without damaging pipe materials. These solutions work well for addressing routine scaling in pipes but may be insufficient for severe tuberculation in pipe systems.

Municipal sewer systems frequently utilize specialized equipment that combines mechanical scraping with powerful vacuum extraction for comprehensive pipe scale removal.

Industrial facilities traditionally employ mechanical pipe descaling techniques, including high-pressure water jetting, rotary cutting tools, and pigging systems. These approaches address significant pipe scale without requiring complete replacement. However, they often require process downtime and can take up a lot of resources. Many industrial operations also integrate fouling deposits removal with their clean-in-place protocols to ensure comprehensive system hygiene.

Advanced Ultrasound Technology

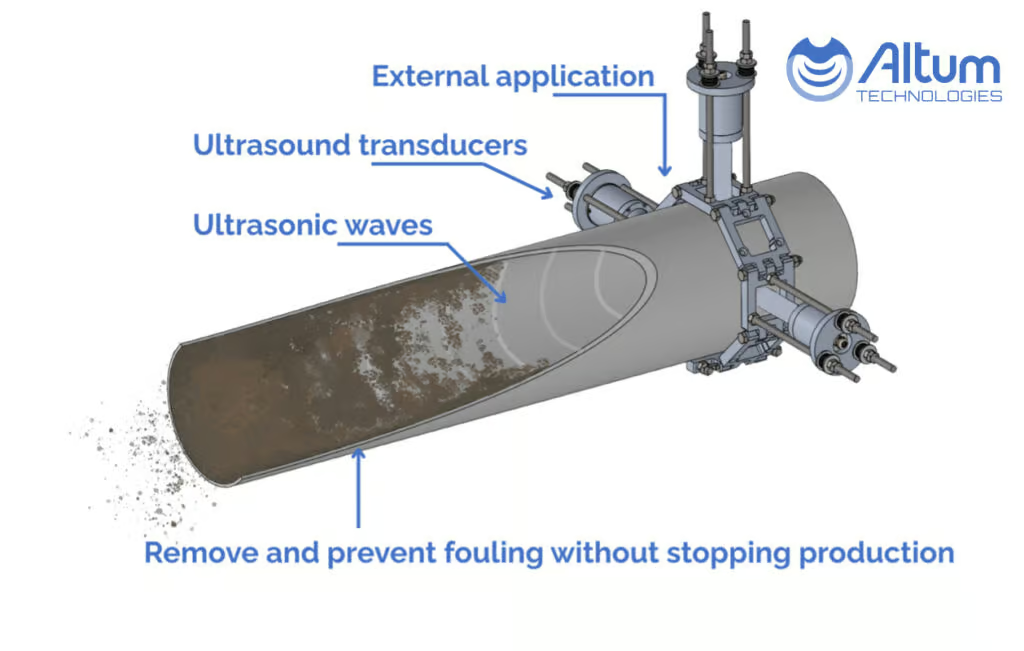

Altum Technologies offers an innovative approach to pipe fouling with a high-power ultrasound solution. This technology uses precisely targeted sound waves to both prevent and remove scaling in pipes without requiring system shutdown or chemical treatments, which makes it an efficient method for industrial descaling.

The non-invasive ultrasound penetrates pipe walls to break down existing deposits while preventing new scale formation, making it an effective anti-scaling solution for industrial pipework. This sustainable pipe descaling method works effectively across various materials and is particularly valuable in industrial settings where continuous operation is critical. Unlike traditional pipe scale removal methods, Altum’s ultrasound technology addresses fouling issues while systems remain fully operational. And unlike traditional CIP systems, it doesn’t require extensive infrastructure.

Prevention Strategies

Preventing fouling in pipes is always preferable to reactive pipe descaling. Consider implementing water treatment systems, regular maintenance schedules, appropriate material selection, and monitoring programs to minimize fouling development. For industrial applications, preventative solutions like Altum Technologies’ ultrasound system can continuously protect pipes from scaling and tuberculation, significantly reducing maintenance requirements and extending equipment lifespan.

By understanding the unique characteristics of pipe fouling, whether scaling, tuberculation, or other deposit types, system operators can implement appropriate descaling strategies that extend infrastructure lifespan, maintain operational efficiency, and reduce long-term costs.

Would you like to learn more about preventing fouling in industrial pipes with ultrasound? Contact our experts for a free assessment.

Follow us on LinkedIn so you won’t miss our future news and insights.