Manufacturing facilities, refineries, and power plants face some of their most challenging operational periods during STO events: shutdowns, turnarounds, or outages. These planned or unplanned maintenance events can cost millions of dollars and significantly impact production schedules. Implementing effective strategies to minimize downtime is crucial for industrial operations worldwide.

What is STO and Why Does It Matter?

Shutdown, turnaround and outage, STO, refers to stoppages of operations in industrial facilities to perform essential maintenance, repairs, and upgrades that cannot be completed during normal operations. The term STO encompasses three distinct but related types of maintenance events: shutdowns (temporary, often planned partial stop for maintenance not necessarily concerning the whole plant), turnarounds (comprehensive maintenance, renovation and inspection cycles that halt production in the whole plant), and outages (unplanned or emergency stops, can impact the whole plant or a specific part).

A turnaround is the most complex and comprehensive stoppage of the three. During a plant turnaround, facilities typically face several challenges including extended downtime, high labor costs, safety risks, and potential delays that can cause significant financial losses. Refineries, chemical plants, and power generation facilities rely heavily on effective turnaround management to minimize these impacts while ensuring all critical maintenance is completed safely and efficiently.

Strategic Turnaround Management and Planning

Effective turnaround management begins months or even years before the actual shutdown. Turnaround maintenance planning involves detailed coordination of multiple areas including mechanical, electrical, instrumentation, and civil work. The complexity of modern plant turnaround operations requires sophisticated project management approaches to ensure success.

A comprehensive turnaround plan typically includes scope definition, resource planning, scheduling, safety protocols, and quality assurance measures. Turnaround management consulting services often provide specialized expertise to help facilities optimize their planning processes and execution strategies.

Critical elements of successful turnaround planning include:

Work scope identification and prioritization based on equipment condition assessments and reliability data. Preventive maintenance programs provide valuable insights into equipment health, enabling more accurate scope development for upcoming turnarounds.

Resource planning and scheduling that accounts for skilled labor availability, equipment requirements, and material procurement. Early identification of maintenance needs through preventive programs allows for better resource planning and cost control.

Safety planning and risk assessment to protect workers during the intensive maintenance period. Well-maintained equipment typically presents fewer safety hazards during turnaround work. In addition, non-invasive methods for cleaning equipment can significantly lower safety risks.

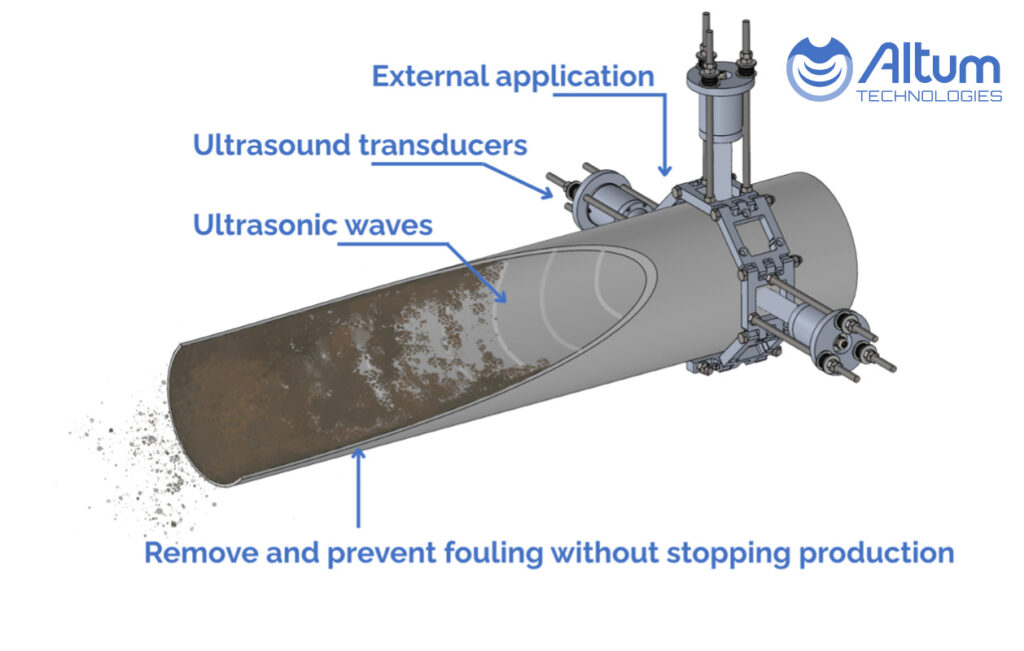

Planning turnaround cleaning services represent another critical component of STO operations. Industrial cleaning during turnarounds often requires specialized techniques and equipment to safely remove process deposits, contaminants, and debris that could impact equipment performance or safety. We here at Altum Technologies can provide an efficient, non-invasive cleaning solution based on ultrasound. Or, even better, prevent buildup altogether by enabling effective preventive maintenance.

The Role of Preventive Maintenance in STO Success

Preventive maintenance serves as the foundation for successful turnaround maintenance planning, with fouling prevention being one of the most impactful strategies facilities can implement. Fouling, the accumulation of unwanted deposits on heat exchanger surfaces, piping, and other process equipment, represents one of the largest contributors to extended STO durations and costs.

When fouling is allowed to accumulate, it causes extensive cleaning operations that can add weeks to turnaround schedules and require specialized turnaround cleaning services at significant cost. In addition, fouling can cause frequent unplanned outages if equipment becomes severely clogged or inoperable, and equipment might even need to be replaced. Factory maintenance programs that emphasize fouling prevention help facilities dramatically reduce cleaning requirements during plant shutdowns and turnarounds and decrease or eliminate the need for frequent outages.

The impact of effective fouling prevention on STO operations includes:

- Dramatically reduced cleaning time during shutdowns and turnarounds

- No unplanned, emergency outages for fouling removal

- Lower requirements for chemical cleaning and specialized cleaning equipment

- Reduced safety risks associated with intensive cleaning operations

- Shorter overall STO durations leading to faster return to production

- Significant cost savings on cleaning services, equipment repairs/replacements and extended downtime

Industry-Specific Applications

Refinery turnaround operations particularly benefit from fouling prevention strategies due to the heavy fouling tendencies of petroleum products. Refineries that implement continuous fouling prevention can reduce their cleaning requirements and cut turnaround durations compared to facilities relying on reactive cleaning approaches.

Power plants face similar fouling challenges, especially in heat recovery systems and condensers. Preventive fouling control helps optimize equipment performance and significantly reduces cleaning requirements during planned outages. Chemical plants, steel mills, and other process industries also see substantial benefits related to STOs when fouling prevention is prioritized over reactive cleaning.

Advanced Technologies for Preventive Maintenance

Modern preventive maintenance programs use advanced technologies to decrease the need for and interval between extensive maintenance activities.

Altum Technologies’ ultrasound solution provides innovative approaches to fouling prevention. By utilizing ultrasound’s properties, like the ability to induce pressure changes or controlled crystallization and create microscopic vibration, Altum’s solution effectively prevents fouling in equipment. It is externally applied to the equipment and doesn’t require any welding or disassembly.

By implementing ultrasonic fouling prevention technology, facilities can maintain cleaner equipment surfaces and reduce the scope of cleaning work required during shutdown, turnaround, or outage periods or extend the time between them. The ability to prevent fouling through ultrasonic technology directly supports turnaround maintenance planning by providing more predictable equipment conditions and reducing uncertainty around cleaning requirements.

Maximizing Turnaround Success

The integration of fouling prevention with comprehensive turnaround planning creates a transformative approach to managing industrial STOs. Facilities that invest in proactive fouling prevention technologies, particularly ultrasonic solutions like those from Altum Technologies, often experience shorter STO durations, lower cleaning costs, and improved overall equipment reliability.

Success in managing shutdowns, turnarounds, and outages increasingly depends on shifting from reactive cleaning during STOs to proactive fouling prevention during normal operations. This paradigm shift allows facilities to minimize cleaning requirements, reduce safety risks, and optimize their maintenance strategies for maximum uptime.

The ultimate goal is creating a sustainable balance between operational availability and maintenance requirements. This ensures facilities can meet production demands while maintaining safe, reliable operations throughout their lifecycle.

Would you like to learn more about using ultrasound for preventive maintenance to help with STO management? Don’t hesitate to contact our experts!

Follow us on LinkedIn so you won’t miss our future news and insights.