Pipes play a vital role in industrial processes, serving as the backbone for transporting materials, for example, liquids like black liquor, brine, and oil. Pipes are also very vulnerable to fouling and scaling, which can cause significant issues in industrial processes. Fouling, sometimes also referred to as scaling, is the accumulation of unwanted material on solid surfaces, and has become a major industrial problem that companies spend billions of dollars to combat. Overtime, this build up constricts the diameter of the pipe, impacting the flow and putting pressure on pump performance, in addition to weakening heat transfer efficiency. This makes industrial pipe maintenance an important issue in many production processes.

Plant operators face recurring challenges including the need for complete system shutdowns, and safety risks during manual cleaning operations. Traditional methods often involve harsh chemicals that pose environmental concerns, mechanical interventions that can damage pipe interiors and require manual labor and often consist of reactive approaches that address problems only after significant fouling has occurred. Fouling removal tactics can prove to be costly, not to mention the lost profits from frequent production stops.

This article will introduce challenges related to fouling in pipes and an effective solution for industrial pipe maintenance, high-power ultrasound.

Common Pipe Fouling Challenges

Fouling in industrial pipes is a common issue across industries, caused by substances like calcium carbonate, struvite, biofilm, or rust, depending on the process. Despite the different types of fouling, the problems they cause are similar:

- Reduced flow efficiency in the pipeline

- Decreased heat transfer efficiency

- Pressure loss

- Negatively impacting the whole pipeline, such as putting extra pressure on pumps

- Maintenance challenges and frequent production stops for cleaning

- Increased emissions: Weakened heat transfer and energy efficiency lead to higher energy consumption and CO2 emissions

While solutions like coatings and chemical cleaning can mitigate fouling, many methods still require manual or mechanical intervention, production downtime, or result in harmful chemical emissions and increased water usage. An alternative is using ultrasound, which effectively prevents fouling without disrupting the process.

Altum’s Ultrasound Technology for Effective Industrial Pipe Maintenance

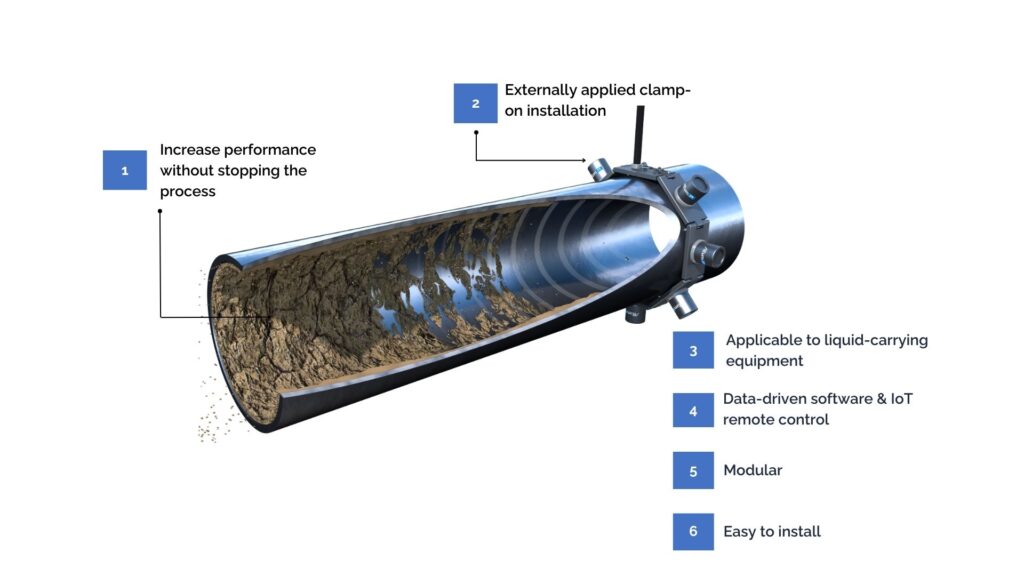

Since preventing any fouling in pipes is crucial in many ways, Altum has good news: Altum’s unique ultrasound technology is an efficient way to tackle fouling in industrial pipes. By utilizing ultrasound’s ability to affect liquids and bonds or to create microvibrations, Altum’s solution is able to prevent fouling from happening or to remove existing buildup. Two properties clearly set it apart from other ultrasound cleaning technologies: the capability to control the ultrasound and external application without making any changes to the process. With our innovative software Altum combines high power capacity with control to focus ultrasound power precisely where it is needed. The system can be monitored and controlled remotely, ensuring optimal performance with minimal effort from the customer.

Physically the solution consists of ultrasonic transducers, which are installed externally to the equipment. This means no welding or changes to the process are necessary, and operations can continue normally while the ultrasound mitigates fouling – real-time fouling prevention for optimal process efficiency.

The benefits of using Altum’s ultrasound technology in pipes include:

- Improved flow rate

- Pump efficiency stays at the designed level, improving energy efficiency and ensuring that the process can function as intended

- Increased process uptime, no unplanned stoppages

- Increased equipment lifetime, due to less blockage, wear, and tear

- Improved end-product quality and overall process stability

- Improved sustainability: lower energy consumption, less chemicals and water needed

Case Example: Results from Nutrien

This site was experiencing fouling challenges in a brine pumping pipeline used for potash production. These challenges were caused by salts precipitating out of the process solution due to significant temperature fluctuations, crystallizing in the line, and attaching to the inner surfaces. The fouling led to frequent maintenance, which disturbed production on a weekly basis. Frequent maintenance also impacted the process’s recovery rates.

Altum’s ultrasound solution was installed on the potash pipeline to prevent scaling and reduce maintenance needs. In this case, Altum’s ultrasound solution affected the scaling locally by creating an ultrasonic field in the equipment which prevents the foulant from attaching to the surfaces.

By preventing fouling, Altum’s solution was able to reduce maintenance requirements by approximately 75% compared to untreated pumps/pipes in the system. This demonstrates the effectiveness of our ultrasound technology in industrial pipe maintenance.

If you’d like to learn more about using Altum’s technology to prevent fouling in industrial pipes, please contact our experts.

Follow us on LinkedIn so you won’t miss our future news and insights.